Construction and dimensions according to EN

734, this design ensure strong self-priming

performance.

- Use and maintenance manual

- Brochure

Field of application

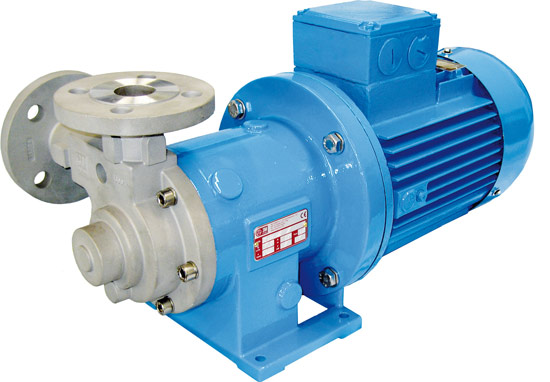

SC MAG-M pumps range meets the requirements on custom-built solutions in the process industry, in the following areas:

Chemical and pharmaceutical, transfer of aggressive, highly corrosive liquids, paper, food processing, plant engineering and construction. For all industries that choose a pumping leak-free and low maintenance for use continuous (abandon of mechanical seal pumps).

Design features

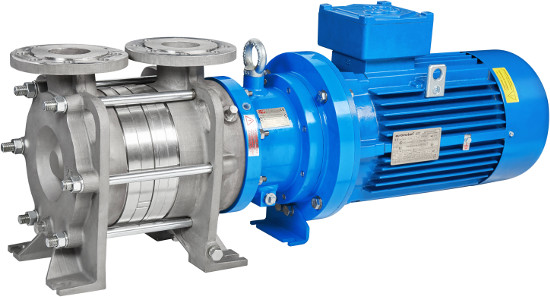

SCE pump series are heavy horizontal self priming, side channel pumps, with top suction and

discharge, designed specifically for clean chemical process, low boiling and highly volatile, explosive

and dangerous liquids, even in presence of high gas percentages.

Low speed operation ensure long life, noiseless performance and reliability.

This pump range is dimensionally corresponding to EN 734.

Materials

Standard execution includes CF8M pump casing,

cover & Duplex 22%Cr impellers High quality

casting components.

Materials as an option:

– Hastelloy®,

– Incoloy®,

– Duplex,

– Others available on request.

SCE series are available with 3 different containment shell configurations:

– Hybrid Containment shell

– HC

– Zero Losses

For more informations of the available containment shell, download the brochure